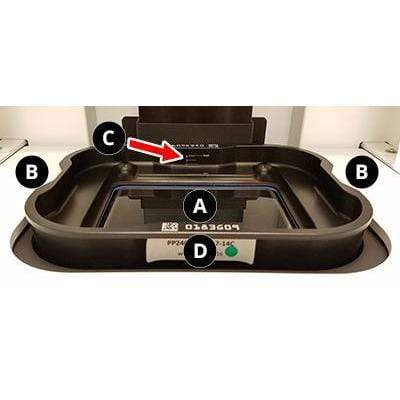

NextDent Resin Tray Kit

VAT will be added at the checkout

Sold out

Original price

£570.00

-

Original price

£570.00

Original price

£570.00

£570.00

-

£570.00

Current price

£570.00