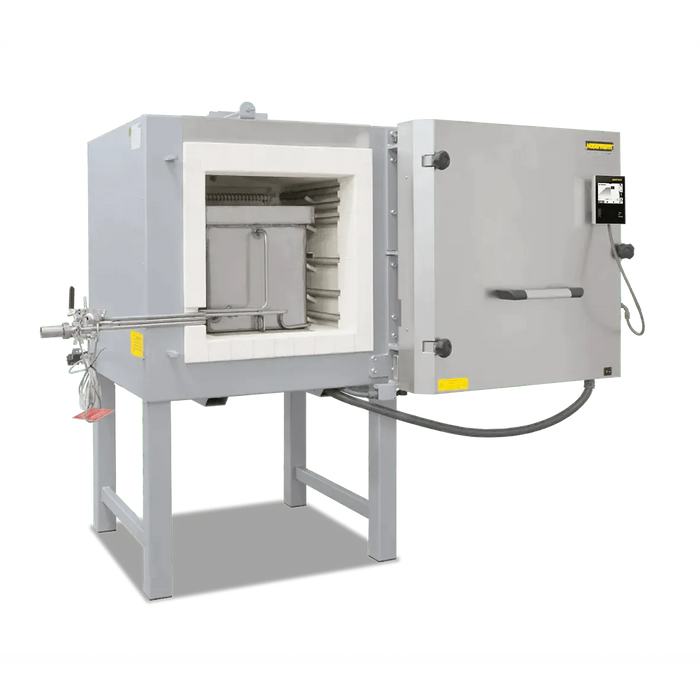

Nabertherm LH 60/12 Chamber Furnace System

VAT will be added at the checkout

Original price

£14,340.00

-

Original price

£14,340.00

Original price

£14,340.00

£14,340.00

-

£14,340.00

Current price

£14,340.00